When you turned off kettle switch but steam supply was not stopped then it still over boiled.

- Share

- Issue Time

- Aug 31,2022

For our initiatory judgment, either solenoid valve or angle seat valve has problem. Here is a testing and solution summary.

1. solenoid valve: you need two people together to check, one person in the console control switch, the other person to check in the boot or close, the state of the solenoid valve.

A:The indicator light of solenoid valve is on in the closed state, it shows it is the bad one. Pull out the pipe of the solenoid valve with the problem. If the solenoid valve is out of air, there may be problem with the solenoid valve. In this situation, you maybe need to change the Solenoid valve.

B: If the solenoid valve does not vent, then the solenoid valve may be ok.

2.Angle valve:

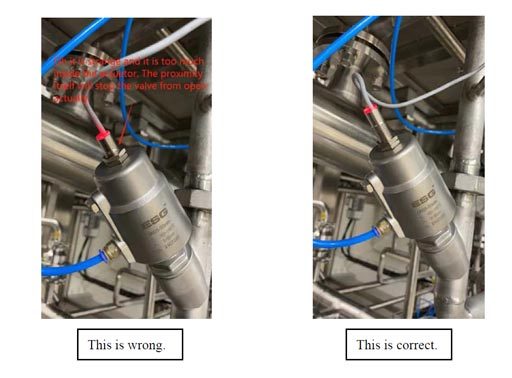

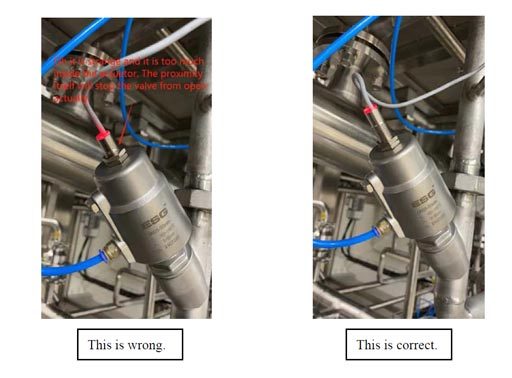

A:Is the Angle seat valve fitted with valve feedback device (proximity switch)? If you have, look for reaction when the valve is closed or opened. If not, when closing or opening the valve, look at the sight glass above the Angle seat valve cylinder there is an orange indicator rod, under normal circumstances, the red indicator rod will be seen when the valve is opened. And the red indicator rod can not be seen when the valve is closed. In this situation, the angle seat valve is ok.

B:The compressed air can also be directly connected to the air inlet hole of the cylinder without the solenoid valve, the ventilation valve is opened, the gas source is closed, and the valve is closed, proving that the valve is good.

C:when switching the solenoid valve, if the Angle valve actuator does not make a "kaka" sound, it may be that the Angle valve is stuck. If stuck, the biggest possibility is that the cylinder spring is broken, the valve can not automatically close, even through the compressed air or off the compressed air, the valve does not move.

If your problem is similar to the above, follow these steps to try it out.

If you want to get more information, please contact with:

Jessica Zhao

Mobile: +86-139 4086 7350

Email: jessica.z@dymbrewing.com